69 to 82 % Nickel-Iron

Highest Permeability for Demanding Magnetic Sensor Applications

Nickel-iron materials are characterized by their high permeabilities, which perfectly suits demanding applications where the highest accuracy in magnetic sensing is necessary. Due to their high permeability and the low coercivity, NiFe alloys with a nickel content of 69 % to 82 % are the best choice for these applications.

Benefits:

-

Highest permeability leads to a very high shielding factor

-

Lowest coercivity

MUMETALL® is intended for soft magnetic cores or parts. VACOPERM® 100 and the different grades of ULTRAPERM® have the same alloy composition. They differ in the level of initial and maximum permeability, rising from VACOPERM 100 up to the superior grade ULTRAPERM 250.

MUMETALL and VACOPERM alloys are mainly used in current transformers, magnetic shielding and parts for sensors.

The group of ULTRAPERM alloys is used mainly for high permeability cores, e.g. for differential current transformers in residual current devices (RCDs).

MUMETALL® and VACOPERM® 100 are copper containing alloys with 77%Ni-4,5%Cu-4,5%Mo and the magnetostriction constant λ111 adjusted to zero. The alloys in this group are very soft magnetic materials. They are available in various tape thicknesses as well as in a solid material form. Their characteristic is high output and maximum permeabilities as well as low coercitivity field strengths with saturation polarizations (around 0.7 - 0.8 T). In addition, the shape of the hysteresis loop can be manipulated in very broad limits. For example, it is possible to create circular tape cores with rectangular loops (Z), round loops (R) and flat loops (F).

MUMETALL® is intended for soft magnetic cores or parts. VACOPERM® 100 and the different grades of ULTRAPERM® have the same alloy composition. They differ in the level of initial and maximum permeability, rising from VACOPERM 100 up to the superior grade ULTRAPERM 250.

MUMETALL and VACOPERM alloys are mainly used in current transformers, magnetic shielding and parts for sensors.

The group of ULTRAPERM alloys is used mainly for high permeability cores, e.g. for differential current transformers in residual current devices (RCDs).

MUMETALL® and VACOPERM® 100 are copper containing alloys with 77%Ni-4,5%Cu-4,5%Mo and the magnetostriction constant λ111 adjusted to zero. The alloys in this group are very soft magnetic materials. They are available in various tape thicknesses as well as in a solid material form. Their characteristic is high output and maximum permeabilities as well as low coercitivity field strengths with saturation polarizations (around 0.7 - 0.8 T). In addition, the shape of the hysteresis loop can be manipulated in very broad limits. For example, it is possible to create circular tape cores with rectangular loops (Z), round loops (R) and flat loops (F).

| Alloy | Mass Density ρ [g/cm3] |

Electrical Density ρel [μΩm] |

Curie Temperature TC [°C] |

Thermal Conductivity λ [W/mK] |

|---|---|---|---|---|

| MUMETALL | 8.7 | 0.55 | 400 | 17 - 19 |

| VACOPERM 100 | 8.7 | 0.6 | 500 | 17 - 19 |

| ULTRAPERM | 8.7 | 0.6 | 360 | 17 - 19 |

| Alloy | Mass Density ρ [g/cm3] |

Electrical Density ρel [μΩm] |

Curie Temperature TC [°C] |

Thermal Conductivity λ [W/mK] |

|---|---|---|---|---|

| MUMETALL | 8.7 | 0.55 | 400 | 17 - 19 |

| VACOPERM 100 | 8.7 | 0.6 | 500 | 17 - 19 |

| ULTRAPERM | 8.7 | 0.6 | 360 | 17 - 19 |

Downloads

Related Products

40 % to 50 % Nickel-Iron

Alloys with a Ni-content of around (40...50) wt% are characterized by a maximum in the saturation polarisation of up to JS = 1.6 T and a medium range permeability. By selecting appropriate rolling and annealing conditions, the shape of the magnetization curve can be varied over a wide range.

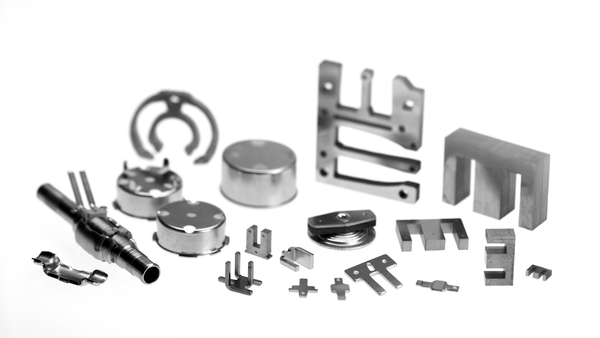

Soft Magnetic Stamped Parts

All crystalline alloys can be processed further to stamped parts. VAC has state-of-the-art facilities for punching, deep-drawing and further processing methods like interlocking or wire-EDM.

Automation and Drives

Our soft magnetic nickel-iron alloys are designed for cores or parts. They are used in current transformers, magnetic shields and parts for sensors.

Contact Us Think Global - Act Local

We are looking forward to support you.