9 to 27 % Cobalt-Iron VACOFLUX

Cost Optimized Cobalt-Iron Alloys with a High Saturation Polarization

Cobalt-Iron alloys in general have a very high polarization saturation. This group of CoFe alloys, with a reduced cobalt content of 9 - 27% cobalt, are optimized to meet the requirements of technically demanding, however cost sensitive applications.

Benefits:

- Reduced cost level due to lower cobalt contents

-

Optimized product parameters for dedicated applications

Strip material

- Electric motors and generators (VACOFLUX® X1)

- Magnetic actuators (VACOFLUX® 17, 18 HR and 9 CR)

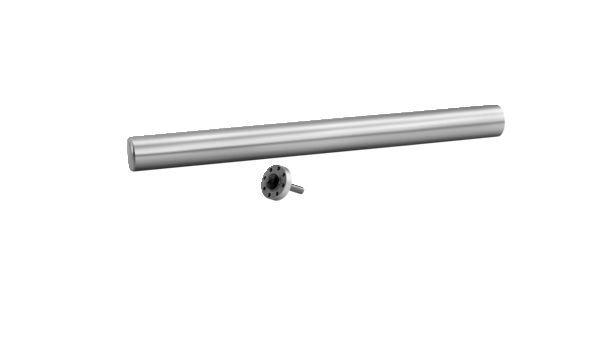

Solid material

- Magnetic actuators (VACOFLUX® 17, 18 HR and 9 CR)

- Flux guiding parts (VACOFLUX® 27)

Forms of Supply

| Alloy | Description | Form of Delivery | ||

|---|---|---|---|---|

| Strip | Rods / Wires | |||

| VACOFLUX X1 | New alloy which is closing the gap between electrical steel and 49 % cobalt-iron qualities | ✔ | ||

| VACOFLUX 17 | Cost optimized cobalt-iron grade for magnetic actuators | ✔ | ✔ | |

| VACOFLUX 18 HR | Special cobalt-iron quality with outstanding resistivity of 0.6 µΩm for high dynamic applications | ✔ | ||

| VACOFLUX 9 CR | Corrosion resistant material for applications in aggresive enviroments | ✔ | ||

| VACOFLUX 27 | Alloy with extremly high saturation of 2.38 T for static applications | ✔ | ||

Strip material

- Electric motors and generators (VACOFLUX® X1)

- Magnetic actuators (VACOFLUX® 17, 18 HR and 9 CR)

Solid material

- Magnetic actuators (VACOFLUX® 17, 18 HR and 9 CR)

- Flux guiding parts (VACOFLUX® 27)

Forms of Supply

| Alloy | Description | Form of Delivery | ||

|---|---|---|---|---|

| Strip | Rods / Wires | |||

| VACOFLUX X1 | New alloy which is closing the gap between electrical steel and 49 % cobalt-iron qualities | ✔ | ||

| VACOFLUX 17 | Cost optimized cobalt-iron grade for magnetic actuators | ✔ | ✔ | |

| VACOFLUX 18 HR | Special cobalt-iron quality with outstanding resistivity of 0.6 µΩm for high dynamic applications | ✔ | ||

| VACOFLUX 9 CR | Corrosion resistant material for applications in aggresive enviroments | ✔ | ||

| VACOFLUX 27 | Alloy with extremly high saturation of 2.38 T for static applications | ✔ | ||

Product Details

Strip Material

| Alloy | Thickness t [mm] |

Coercivity HC [A/m] |

max. Permeability µmax |

Saturation Polarization JS [T] |

Induction @ 800 A/m B800 [T] |

Iron Loss @ 1.5 T/ 50 Hz PFE1.5/50 [W/kg] |

Iron Loss @ 1.5 T/ 1 kHz PFE1.5/1k [W/kg] |

Iron Loss @ 2 T/ 50 Hz PFE2/50 [W/kg] |

Iron Loss @ 2 T/ 1 kHz PFE2/1k [W/kg] |

Saturation Magneto-striction λS [ppm] |

|---|---|---|---|---|---|---|---|---|---|---|

| VACOFLUX 17 | 0.35 | 100 | 3,500 | 2.2 | 1.5 | 3.8 | 223 | 7.0 | 400 | +25 |

| VACOFLUX X1 | 0.2 | 50 | 15,000 | 2.2 | 1.7 | 2.1 | 144 | 5.0 | 490 | +25 |

Solid Material

| Alloy | Coercivity HC [A/m] |

max. Permeability µmax |

Saturation Polarization JS [T] |

Polarization @ 10 kA/m J10k [W/kg] |

Polarization @ 20 kA/m J20k [W/kg] |

Polarization @ 40 kA/m J40k [W/kg] |

Saturation Magnetostriction λS [ppm] |

|---|---|---|---|---|---|---|---|

| VACOFLUX 9 CR | 130 | 3,000 | 1.80 | 1.70 | 1.76 | 1.80 | +30 |

| VACOFLUX 17 | 140 | 3,200 | 2.22 | 1.94 | 2.09 | 2.19 | +25 |

| VACOFLUX 18 HR | 170 | 2,500 | 2.09 | 1.87 | 2.00 | 2.06 | +25 |

| VACOFLUX 27 | 150 | 3,000 | 2.38 | 2.11 | 2.27 | 2.38 | +40 |

Strip Material

| Alloy | Thickness t [mm] |

Yield Strength Rp0.2 [MPa] |

Tensile Strength Rm [MPa] |

Young's Modulus E [GPa] |

Elongation A [%] |

Hardness HV10 |

|---|---|---|---|---|---|---|

| VACOFLUX 17 | 0.35 | 250 | 450 | 200 | 32 | 140 |

| VACOFLUX X1 | 0.2 | 130 | 270 | 210 | 10 | 110 |

Solid Material

| Alloy | Yield Strength Rp0.2 [MPa] |

Tensile Strength Rm [MPa] |

Young's Modulus E [GPa] |

Elongation A [%] |

Hardness HV10 |

|---|---|---|---|---|---|

| VACOFLUX 9 CR | 330 | 490 | 180 | 35 | 170 |

| VACOFLUX 17 | 250 | 450 | 200 | 32 | 140 |

| VACOFLUX 18 HR | 400 | 600 | 210 | 28 | 200 |

| VACOFLUX 27 | 240 | 550 | 200 | 30 | 170 |

Strip Material

| Alloy | Thickness t [mm] |

Density ρ [g/cm3] |

Electrical Resistivity ρel [μΩm] |

Expansion Coefficient (20...200 °C) α [10-6/K] |

Thermal Conductivity (25 °C) λ [W/(mK)] |

Curie Temperature TC [°C] |

|---|---|---|---|---|---|---|

| VACOFLUX 17 | 0.35 | 7.94 | 0.41 | 10.8 | 34 | 950 |

| VACOFLUX X1 | 0.2 | 7.90 | 0.30 | 11 | 35 | 940 |

Solid Material

| Alloy | Density ρ [g/cm3] |

Electrical Resistivity ρel [μΩm] |

Expansion Coefficient (20...200 °C) α [10-6/K] |

Thermal Conductivity (25 °C) λ [W/(mK)] |

Curie Temperature TC [°C] |

|---|---|---|---|---|---|

| VACOFLUX 9 CR | 7.75 | 0.79 | 10.9 | 20 | 800 |

| VACOFLUX 17 | 7.94 | 0.41 | 10.7 | 34 | 920 |

| VACOFLUX 18 HR | 7.81 | 0.65 | 10.5 | 25 | 920 |

| VACOFLUX 27 | 7.99 | 0.15 | 10.8 | 67 | 950 |

Strip Material

| Alloy | Thickness t [mm] |

Coercivity HC [A/m] |

max. Permeability µmax |

Saturation Polarization JS [T] |

Induction @ 800 A/m B800 [T] |

Iron Loss @ 1.5 T/ 50 Hz PFE1.5/50 [W/kg] |

Iron Loss @ 1.5 T/ 1 kHz PFE1.5/1k [W/kg] |

Iron Loss @ 2 T/ 50 Hz PFE2/50 [W/kg] |

Iron Loss @ 2 T/ 1 kHz PFE2/1k [W/kg] |

Saturation Magneto-striction λS [ppm] |

|---|---|---|---|---|---|---|---|---|---|---|

| VACOFLUX 17 | 0.35 | 100 | 3,500 | 2.2 | 1.5 | 3.8 | 223 | 7.0 | 400 | +25 |

| VACOFLUX X1 | 0.2 | 50 | 15,000 | 2.2 | 1.7 | 2.1 | 144 | 5.0 | 490 | +25 |

Solid Material

| Alloy | Coercivity HC [A/m] |

max. Permeability µmax |

Saturation Polarization JS [T] |

Polarization @ 10 kA/m J10k [W/kg] |

Polarization @ 20 kA/m J20k [W/kg] |

Polarization @ 40 kA/m J40k [W/kg] |

Saturation Magnetostriction λS [ppm] |

|---|---|---|---|---|---|---|---|

| VACOFLUX 9 CR | 130 | 3,000 | 1.80 | 1.70 | 1.76 | 1.80 | +30 |

| VACOFLUX 17 | 140 | 3,200 | 2.22 | 1.94 | 2.09 | 2.19 | +25 |

| VACOFLUX 18 HR | 170 | 2,500 | 2.09 | 1.87 | 2.00 | 2.06 | +25 |

| VACOFLUX 27 | 150 | 3,000 | 2.38 | 2.11 | 2.27 | 2.38 | +40 |

Strip Material

| Alloy | Thickness t [mm] |

Yield Strength Rp0.2 [MPa] |

Tensile Strength Rm [MPa] |

Young's Modulus E [GPa] |

Elongation A [%] |

Hardness HV10 |

|---|---|---|---|---|---|---|

| VACOFLUX 17 | 0.35 | 250 | 450 | 200 | 32 | 140 |

| VACOFLUX X1 | 0.2 | 130 | 270 | 210 | 10 | 110 |

Solid Material

| Alloy | Yield Strength Rp0.2 [MPa] |

Tensile Strength Rm [MPa] |

Young's Modulus E [GPa] |

Elongation A [%] |

Hardness HV10 |

|---|---|---|---|---|---|

| VACOFLUX 9 CR | 330 | 490 | 180 | 35 | 170 |

| VACOFLUX 17 | 250 | 450 | 200 | 32 | 140 |

| VACOFLUX 18 HR | 400 | 600 | 210 | 28 | 200 |

| VACOFLUX 27 | 240 | 550 | 200 | 30 | 170 |

Strip Material

| Alloy | Thickness t [mm] |

Density ρ [g/cm3] |

Electrical Resistivity ρel [μΩm] |

Expansion Coefficient (20...200 °C) α [10-6/K] |

Thermal Conductivity (25 °C) λ [W/(mK)] |

Curie Temperature TC [°C] |

|---|---|---|---|---|---|---|

| VACOFLUX 17 | 0.35 | 7.94 | 0.41 | 10.8 | 34 | 950 |

| VACOFLUX X1 | 0.2 | 7.90 | 0.30 | 11 | 35 | 940 |

Solid Material

| Alloy | Density ρ [g/cm3] |

Electrical Resistivity ρel [μΩm] |

Expansion Coefficient (20...200 °C) α [10-6/K] |

Thermal Conductivity (25 °C) λ [W/(mK)] |

Curie Temperature TC [°C] |

|---|---|---|---|---|---|

| VACOFLUX 9 CR | 7.75 | 0.79 | 10.9 | 20 | 800 |

| VACOFLUX 17 | 7.94 | 0.41 | 10.7 | 34 | 920 |

| VACOFLUX 18 HR | 7.81 | 0.65 | 10.5 | 25 | 920 |

| VACOFLUX 27 | 7.99 | 0.15 | 10.8 | 67 | 950 |

Downloads

Related Products

VACOFLUX® X1

High power combined with low weight is a central feature of motors built with this new low-cobalt-content alloy. Typically, motors can be realised that have a 20 to 30 % higher power density than with electrical steel.

49 % Cobalt-Iron

Due to their high magnetic saturation and low coercivity, the cobalt-iron alloys VACOFLUX and VACODUR offer the best possible conditions for powerful electric motors/generators and magnetic actuators. .

Lamination Stacks

Lamination stacks are packages using single laminations separated by electrical insulating layers to surpress eddy current losses during dynamic magnetic load.

Contact Us Think Global - Act Local

We are looking forward to support you.