Positioning Sensors

40 to 50 % Nickel-Iron Alloys PERMENORM®

Alloys with a Ni-content of around (40 to 50) wt% are characterized by a maximum in the saturation polarisation of up to JS = 1.6 T and a medium range permeability. By selecting appropriate rolling and annealing conditions, the shape of the magnetization curve can be varied over a wide range.

69 to 82 % Nickel-Iron MUMETALL®

These high permeability materials differ mainly in the level of permeability. Permeability increases in the series from the standard grade MUMETALL® to the highest grade ULTRAPERM® 250.

VACOPERM® 100 D is solid material.

MUMETALL and VACOPERM 100 are copper containing alloys with the magnetostriction constant λ111 adjusted to zero. MUMETALL is intended for soft magnetic cores or parts. VACOPERM 100 and the different grades of ULTRAPERM have the same alloy composition. They differ in the level of initial and maximum permeability, rising from VACOPERM 100 up to the superior grade ULTRAPERM 250.

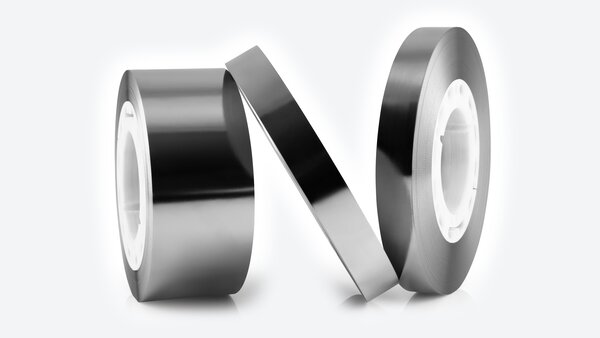

Amorphous Material VITROVAC®

VITROVAC® alloys are magnetically soft but mechnically hard, with a high elastic limit. Properties comprise highest saturation flux density and excellent permeability, making it the ideal solution for applications like electronic article surveillance, flexible antennae, magnetic sensors, magnetic shielding, switching cores in accelerators or power transformers.

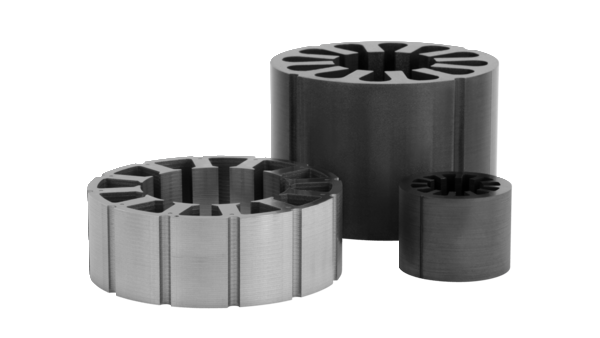

Lamination Stacks

Lamination stacks are packages using single laminations separated by electrical insulating layers to surpress eddy current losses during dynamic magnetic load.

In-house manufactured cobalt-iron or nickel-iron strips in combination with adjusted production technologies are offering optimum stack solutions with respect to performance and costs.

These parts are mainly used as stators and rotors in electric motors and generators but also as laminated cores.

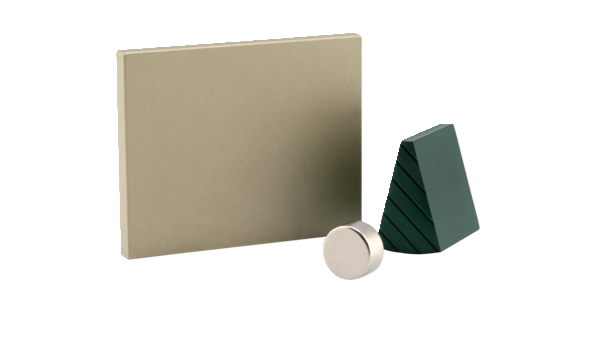

Magnet Assemblies

We are your reliable partner when it comes to the development and production of a wide range of magnet assemblies. The positioning of magnets with extreme precision, especially small one, and the very high forces associated with large-volume magnetized parts, make the assembling of magnet systems a challenging task. For this process we can apply our extensive experience in the design and construction of assembly tools and our expert knowledge in the selection of a suitable bonding process.

Nanocrystalline Material VITROPERM®

VITROPERM® is an iron-based nanocrystalline material with an outstanding combination of soft-magnetic properties which make it the state-of-the-art material for a wide range of applications, e.g. common mode chokes (CMCs), current transformers (CTs), EMI filters and shielding material in wireless power transfer.

NdFeB – VACODYM® Rare Earth Permanent Magnets for Highest Energy Density Requirements.

VACODYM® permanent magnets are produced on the basis of neodymium-iron-boron alloys and have the highest energy density available today. VACODYM alloys are anisotropic material grades.

SmCo – VACOMAX® Rare Earth Permanent Magnets for High Temperature Applications.

VACOMAX® is our permanent magnet material made from rare earths and cobalt. These magnets have particularly high coercivities with simultaneous high saturation polarization and excellent temperature and corrosion stability.

Soft Magnetic Parts

All crystalline alloys can be processed further to stamped parts. VACUUMSCHMELZE has state-of-the-art facilities for punching, deep-drawing and further processing methods like interlocking or wire-EDM.